Dropli

Creating EUV Light with Incredibly Short Wavelengths

Industry: Semiconductors & Photonics (EUV Lithography R&D)

Technology: Custom multilayer PCB design

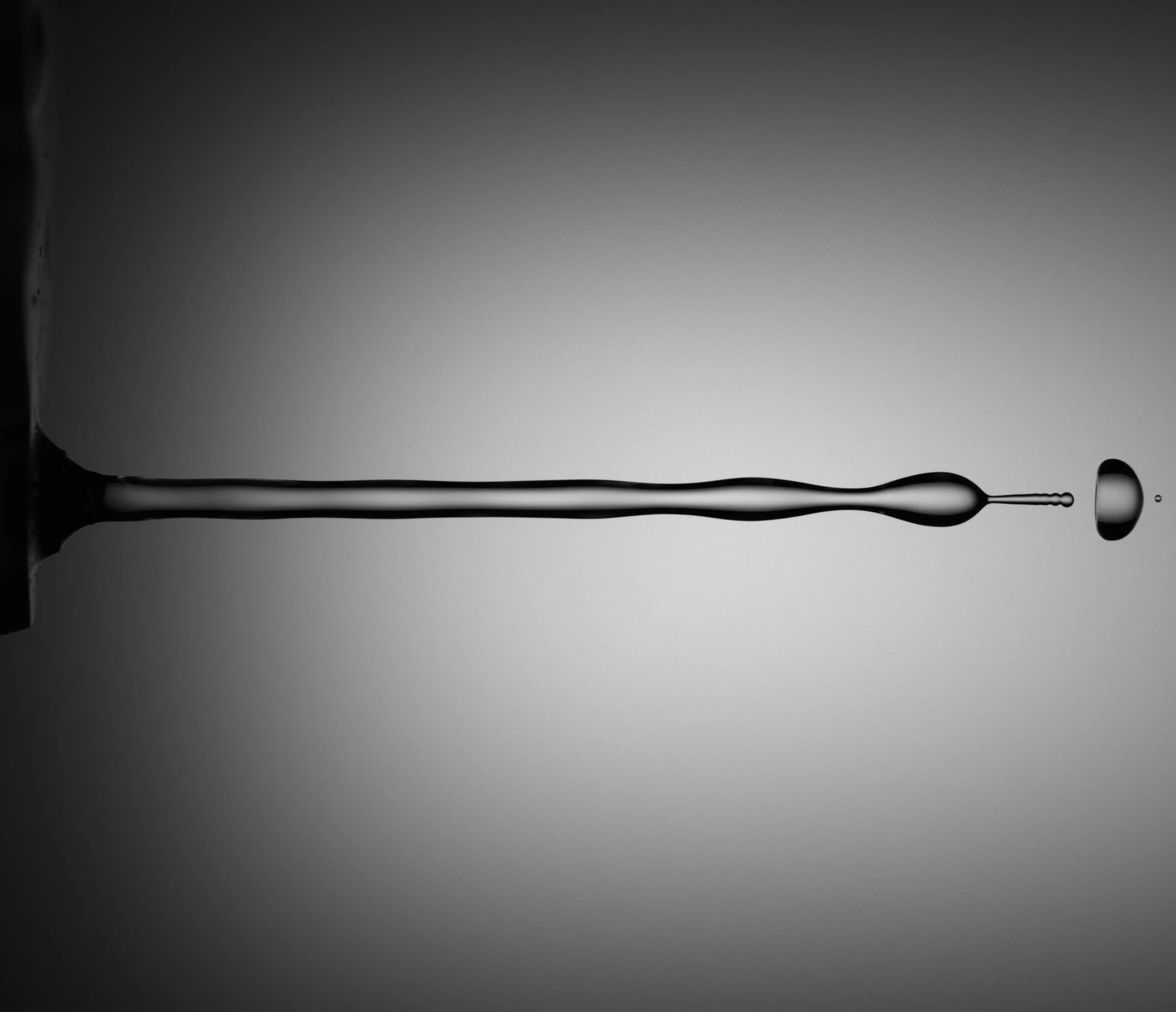

Bestronics Development partnered with Dropli on a demonstrator that explores how high-frequency microfluidic droplet generation can accelerate early-stage semiconductor research. The setup uses water droplets to emulate the behavior of molten tin in Extreme Ultraviolet (EUV) light sources, enabling safe, fast iteration on concepts that underpin advanced lithography.

Client and Goals

Dropli develops microfluidic solutions for research and industrial use. The project aimed to build a reliable demonstrator capable of producing ultra-consistent, high-frequency droplets so researchers could study timing, stability, and interaction effects relevant to EUV light-source development—without the complexity and risk of molten metals.

Challenges

Creating uniform droplets at elevated frequencies demands tight control over drive signals and measurement paths. The system needed low-jitter timing to coordinate actuation, sensing, and potential laser-trigger events, while preserving signal integrity in a noise-sensitive environment. At the same time, the platform had to remain modular and serviceable so R&D teams could adjust parameters quickly and run repeatable experiments.

Bestronics’s Role

We designed the custom multilayer PCB at the heart of the demonstrator, engineering precision analog and digital sections with careful clocking and synchronization to achieve stable high-frequency operation. The layout prioritized low noise, clean return paths, and EMC robustness, and incorporated a laser-trigger-ready interface for EUV-relevant timing studies. We also embedded design-for-manufacture and design-for-test practices and delivered clear electrical documentation to speed bring-up, diagnostics, and iterative refinements.

EUV lithography (~13.5 nm) generates light by hitting tin droplets mid-air with a CO₂ laser to create plasma.

Our water-based, kHz droplet demonstrator lets researchers precisely assess spacing, size stability, and trigger timing in a safer, controlled setup. Rigorous PCB design de-risks early R&D and speeds the step from lab demo to industrial feasibility.

Check more success stories like Dropli

Vehicle-stop system with end-user safety measures | Product design

Smart Solar motors | Electronics design, UX/UI design